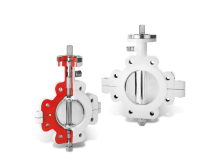

STERILE-SEAL® Butterfly Valves

Valves for Sterile Processes

These valves are used in applications where sterile processes need to be maintained in the pharmaceutical and food industries without unnecessary and costly overhauls and replacement. The special characteristic of this valve is its external sterilization capability. The design is such that the critical “dead” areas of the valve, as well as the disc, body liner, and seals, can be sterilized with steam without coming in contact with the process medium.

- Safety against contamination

- Safety against corrosion

- Safety of the body against over-pressurisation

- Safety by standardization

- Safety against leakages

- Safety by identification

Dimensions

- 2” up to 16” / 5.08 cm up to 40.64 cm

Flange Connection

- ASME B16.5 class 150 lbs (design RF/FF)

- EN 1092 PN 10/16 (Design A/B) (Available upon request)

Face-to-Face Dimensions

- ISO 5752 Table 5 short

- ASME B16.10: 2” to 12” / 5.08 cm to 30.48 cm Table Narrow; 14” to 24” / 35.56 cm to 60.96 cm Table Wide

- DIN EN 558-1 GR 20

- MSS-SP 67: 2” to 12” / 5.08 cm to 30.48 cm Table Narrow; 14” to 24” / 35.56 cm to 60.96 cm Table Wide

- API 609: 2” to 12” / 5.08 cm to 30.48 cm Category A; 14” to 24” / 35.56 cm to 60.96 cm Category B

Body Strength

- DIN/EN 12516 T2 (DIN 3840)

- Tested within the scope of the inspection body designate by Module H1

Operating Pressure

- 145 psi / 10 bar (depending on operating temperature)

Testing

- EN 12266 P10

- EN 12266 P11

- EN 12266 P12 Leak rate A

Bodies

- Water and Lug design with long neck for insulation

Vacuum

- Up to 1 mbar abs. (depending on size and temperature)

Temperature Range

- -40°F / -40°C up to 338°F / 170°C, depending on material

Head Flange

- EN ISO 5211

- NF E 29-402

Liner

- PTFE