VCS SEALING & ISOLATION

Get Professional Help

VCS SEALING & ISOLATION

VCS SEALING & ISOLATION Features

» Extreme, high-reliability sealing and electrical isolation solution for critical service applications

» Seals and isolates all pressure ratings through ANSI 2500 class and API 10,000 psi service

» Withstands severe service conditions including vibration, temperature and pressure fluctuations

» Designed to withstand corrosive environments, including high concentrations of COS, produced water and aggressive inhibitors

» Good electrical isolation properties for cathodic protection

» Pressure-activated seals provide high confidence sealing, eliminates costly leaks and provides a solution for fugitive emissions

» Gasket is sized to the bore to protect flange faces from media-induced corrosion and flow- induced erosion

» Prevents turbulent flow at flanged connections

» Mitigates galvanic corrosion in dissimilar metal flanges

» High-strength laminate material resists failure due to excessive compression

» Available to match any flange specification (ANSI, ASME, API, MSS, BS, DIN, AS, others)

» Can mate mismatched RTJ with raised-face flanges Type E

» Easy installation, make up and removal

» Sealing system is not sensitive to low bolt loads – providing reliable sealing through a range of bolt stress

» Gasket is self-aligning and centering – quick to install and no special tools are required

» Maintenance-free corrosion-resistant design is resistant to deforming under load

» Works in Ring Joint Flanges, reducing fluid entrapment, flow induced erosion and media induced corrosion between flanges

» Reusable by simply replacing sealing ring Type F

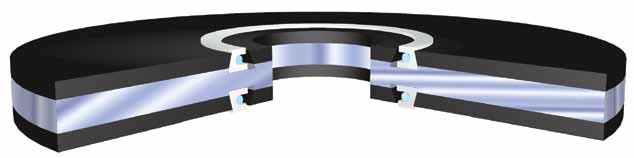

Before tightening

The flange faces come into contact with the sealing elements, which extend slightly above the surface of the retainer. As the flange is tightened  the sealing elements are compressed into the machine groove, developing an initial high unit pressure against the flange faces.

the sealing elements are compressed into the machine groove, developing an initial high unit pressure against the flange faces.

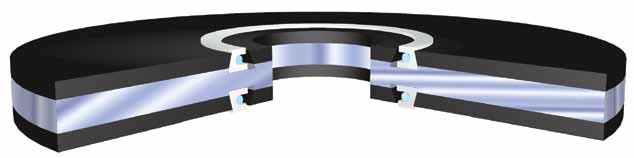

After tightening

The flange faces come into firm contact with the retainer, thus compacting the sealing elements within grooves. At the same time, the unique VCS spring energized seal provides elastic memory for a polymer not normally associated

with this characteristic – resulting in a simple flat gasket with extremely high loading and self-energizing characteristics without adverse cold flow problems.

VCFS Firesafe Isolation

vcfs fIresafe

» Based upon proven GPT VCS platform

» Provides complete flange electrical isolation

» Tandem seal technology

» PTFE sealing system has 20+ years successful track record

» E-Ring sealing systems is dual purpose fire safe and backup

» Passed API 6FB, 3rd Edition Fire Test

» Use in conjunction with cathodic protection systems

» Mitigates potential flange rotation

» Provides a tighter seal under low bolt loads

Before Fire

After Fire

GPT WATER JET AND CNC MACHINES

GPT’s water jet machinery cut intricate parts with no heat-affected zone, distortion, or mechanical stresses caused by other cutting

methods. In addition, they cut with a narrow kerf, to provide better usage of raw material. As a result GPT has the ability to provide

more accurate gaskets, with more intricate shapes and possibilities without wasting raw materials. CNC machines cut precise

dimensions to accommodate specific seal elements and gasket tolerances.